Phenolic Board

Phenolic board is a hard board made of phenolic resin as the base material and processed by foaming or laminating process. It is generated the polymerization reaction of phenol and formaldehyde, and has the characteristics of light weight, fire resistance, heat insulation, low smoke and non-toxic. It to thermosetting plastic materials and is widely used in insulation, decoration and fire protection fields.

Product Description

Phenolic board is a hard board made of phenolic resin as the base material and processed by foaming or laminating process. It is generated the polymerization reaction of phenol and formaldehyde, and has the characteristics of light weight, fire resistance, heat insulation, low smoke and non-toxic. It to thermosetting plastic materials and is widely used in insulation, decoration and fire protection fields.

Cheap phenolic board is renowned for its excellent fireproof performance, featuring non-flammability, no dripping, low smoke and non-toxicity ensuring high safety standards. Its low thermal conductivity ensures superior insulation and heat preservation effects, contributing to significant energy-saving effects.

Product Parameter (Specification)

| Sizes Available | 4*8 | 4.3*10 | 4*12 | 5*10 | 5*12 |

| Thickness Available | 0.5mm | 0.6mm | 0.7mm | 0.8mm | 1mm |

Product Details

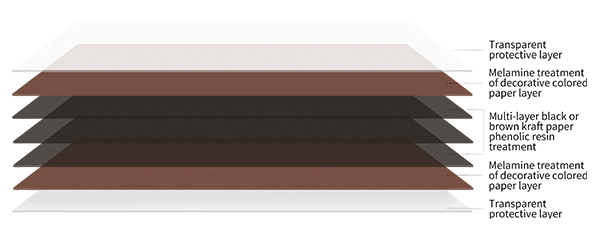

A Phenolic Board is made up of multiple layers of kraft paper saturated with phenolic resin, pressed together at over 150°C and more than 1000 psi of pressure. This manufacturing process produces a board with outstanding density and strength, capable of withstanding mechanical stress and exposure to various chemicals. The outer layer can be a decorative surface impregnated with melamine resin, giving it an attractive finish while maintaining excellent performance.

Phenolic boards come in different thicknesses ranging from 3mm to 25mm, making them suitable for a wide range of applications—from countertops and partitions to structural panels and exterior cladding. They are available in a variety of surface finishes such as matte, gloss, or textured, and can be customized in color and design. The core of the board remains uniformly dense and strong, ensuring consistent performance across its entire surface.

Product Features

Superior Strength and Durability: The high-density phenolic structure provides excellent resistance to impact, abrasion, and mechanical wear, ensuring long-term use even in demanding environments.

Moisture and Water Resistance: The non-porous surface and resin-infused core make the board impervious to moisture, ideal for humid or wet conditions.

Chemical and Heat Resistance: Resistant to acids, alkalis, and other harsh chemicals, as well as high temperatures, making it suitable for laboratories and industrial facilities.

Hygienic and Easy to Clean: The smooth, non-absorbent surface prevents bacterial growth and allows easy cleaning, maintaining hygiene in healthcare and food environments.

Fire and UV Resistance: Designed to meet fire safety and UV protection standards, maintaining structural integrity and color stability.

Variety of Applications: Suitable for use in restroom partitions, kitchen counters, laboratory benches, wall cladding, cabinets, and exterior facades.

Eco-Friendly and Sustainable: Manufactured using low-emission resins and recyclable materials, meeting global environmental requirements.

Product Advantages

Phenolic Boards offer significant advantages over traditional materials like plywood, MDF, or particleboard. Unlike wood-based boards, phenolic boards are highly resistant to water, chemicals, and heat, ensuring they do not swell, crack, or delaminate even under extreme conditions. Their durability makes them ideal for heavy-duty applications such as laboratory worktops, public washrooms, and outdoor furniture.

Additionally, Phenolic Boards are maintenance-free and long-lasting, reducing replacement and maintenance costs. They are lightweight compared to other solid materials, making installation faster and more efficient. The aesthetic versatility of phenolic boards—available in multiple colors and textures—allows designers to achieve both functional and decorative excellence in modern architectural projects.

Compact Laminate

Compact Laminate is a thickened double-faced decorative plate with fire resistance, which is made of special resin and a variety of special papers through high temperature high pressure. Due to its dense density and a variety of changes in color texture and surface treatment, it is suitable for load-bearing countertops, and is also widely used for walls, bathroom partitions, dressing room partitions, space area segmentation, storage cabinets and various countertops, etc.

Product Qualification

We have a one-year warranty period. And we will have corresponding inspections after each process. For the completed products, we will conduct a full inspection according to customer requirements and international standards.

Deliver and Payment method

Usually we ship goods by sea, because we are in Changzhou, we are very close to Shanghai port, and it is very convenient for export by sea. Of course, if the customer's goods are urgent, we can also air freight, Ningbo Airport and Shanghai International Airport are very close to us.

Payment method: When quoting, we will confirm with you the transaction method, FOB, CIF, CNF or other method. During mass production, we usually pay a 30% advance payment first, and then pay the balance on the bill of lading. Most of our payment methods are T/T, of course, L/C is also acceptable.

FAQ

Avoid long-term immersion or exposure to strong acid and alkali environments. Handle with care to prevent damage. Store in a cool and dry place, away moisture and direct sunlight, avoid heavy pressure deformation, and ensure the stability of material properties.