EB-Cured Anti-Fingerprint Panel

EBC electronic beam curing decorative panels, which are treated with a special surface curing technology EBC on the surface of ordinary phenolic resin decorative panels, endow them with super matte skin feel, anti-fingerprint, oil-proof, scratch-resistant and special scratch self-healing properties.

Product Description

EB curing = aerospace grade material + food grade process technology

EBC electronic beam curing decorative panels, which are treated with a special surface curing technology EBC on the surface of ordinary phenolic resin decorative panels, endow them with super matte skin feel, anti-fingerprint, oil-proof, scratch-resistant and special scratch self-healing properties. Compared with ordinary phenolic resin decorative board, because its surface uses a special process of electron beam curing, it brings a unique visual effect, its color is more full, true and pure.

Color representation, product performance, environmental protection and health have achieved an unprecedented unity.

Fusion of technology and design, creating infinite possibilities for custom brands and designers!

The EB-Cured Anti-Fingerprint Panel is a next-generation decorative surface material that perfectly integrates Electron Beam (EB) curing technology with anti-fingerprint (AFP) innovation. Developed to meet the growing demand for high-quality, durable, and easy-to-maintain surfaces, this panel combines sophisticated aesthetics with exceptional functionality. It is ideal for use in premium furniture, cabinetry, wall cladding, and interior design applications.

Four characteristics

Technical

Test

Application field of EB decoration material abroad

25%,outdoor building materials

Resistant to yellowing, aging, and easy to clean 30% for the floor.

45%,Interior decoration

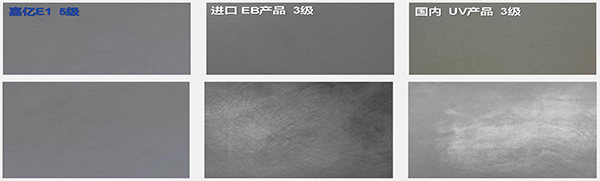

Color representation; anti-fingerprint; ultimate tactile sensation; high performance.

Abrasion resistant, scratch resistant, high performance

Technology and craftsmanship

1.Electron Beam Curing Technology

Fast curing speed: 5 milliseconds to complete curing, which is achieved by using an electron accelerator to generate a high-energy electron beam (typically the range of hundreds of thousands to 3 million EV) that moves at close to the speed of light, directly acting on the resin coating on the surface of the board. After the electron beam penetrates the coating, it produces free radicals by ionization, which the three-dimensional cross-linking reaction of the resin molecular chain, and is cured instantaneously within 0.005 seconds, forming a three-dimensional network structure.

2.Application

Base material selection: Commonly used environmentally friendly base materials such as particleboard, Multi-layer plate , and OSB are generally used, and some high-end use imported rubber wood, etc.

Coating treatment: EB curable resin is coated on the surface of the substrate, and it is safer and more environmentally friendly because it does not need photoinitiator, and it also meets the international development trend of zero VOC emission.

Core advantage:

Scratch resistant; wear resistant; high performance; color representation; anti-fingerprint; ultimate tactile feel.

Extremely high energy: highly concentrated, high utilization rate.

Strong penetration: no color blockage, complete reaction, no residual small molecules, and precise controllable curing depth.

At room temperature curing: no thermal effect, no VOC pollution, no solvent used, no photoinitiator needed.

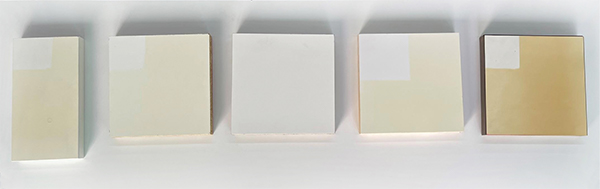

Resistance to yellowing: no color change for ten years.

Anti-aging, easy to clean: no effort, no trace;

Antibacterial: No odor has strong inhibition and killing effect on common pathogens such as Staphylococcus aureus,Escherichia coli and various molds, which can reach ≥99%.

Acid and alkali resistance: can resist the erosion of common acid and alkali solutions used in the laboratory (such as 10% hydrochloric acid, sodium hydroxide), suitable for special environments such as chemical industry medical treatment.

Fire prevention safety: products have passed the B1 grade fireproof certification, will not burn or drip in the presence of an open flame, and meet the fire protection requirements for.

Low-carbon and environmentally friendly

Zero formaldehyde emission: The base material uses non-formaldehyde MDI glue, and the curing process does not require photoinitiator and organic solvents, with formaldehyde emission ≤0.025mg/m³, meeting the ENF grade (the highest domestic environmental protection grade) Japan's F4 star standard.

Food-grade safety: the coating does not contain VOC or heavy metal, and has passed the EU food contact certification, which can be directly used tableware, food packaging and other fields. (For example, the coating of potato chip and coke packaging all uses this technology).

Application fields

1.Custom furniture

Full-house customization: The cabinet doors of the kitchen cabinet, wardrobe, and liquor cabinet are made of EB board, which can achieve seamless splicing, handles, and other integrated designs, taking into account both aesthetics and durability.

Kitchen countertop: Its heat-resistant properties (withstands instantaneous high temperatures of up to 200°C) make it an ideal to quartz stone, especially for open kitchens.

2.Business space

Commercial display: luxury goods counter, museum display cabinet uses EB board, its delicate texture and anti-stain performance can maintain the display effect of the for a long time.

Medical institution: EB antibacterial board is used for the wall panel and instrument cabinet of the operating room, which is smooth and easy to clean, and antibacterial rate is more than 99.9%.

3.Architectural decoration

Facade decoration: EB boards with a thickness of more than 12mm can be used for architectural curtain walls, resistant to ultraviolet and acid rain erosion.

Indoor wall: 3-6mm thin plates are used for feature walls and partitions, which can be matched with different textures (such as Ridge pattern; relief,), and are compatible with modern, minimalist and other design styles.

Product Features

EB Curing Technology

The surface of the panel is treated using electron beam curing, a solvent-free and eco-friendly process that creates a dense, cross-linked molecular structure. This gives the panel excellent hardness, superior scratch resistance, and long-lasting color stability while maintaining a smooth, refined appearance.

Anti-Fingerprint Coating

The advanced AFP surface effectively repels fingerprints, grease, and smudges, ensuring the surface stays clean and visually appealing even after frequent handling. This feature is especially beneficial for high-contact areas such as kitchen cabinets, wardrobe doors, and office furniture.

Soft Matte Finish

The EB-Cured Anti-Fingerprint Panel features a luxurious low-gloss, silky matte texture that enhances both visual and tactile comfort. It provides a subtle, elegant look suitable for modern minimalist interiors and high-end environments.

Durable and Resistant

Thanks to EB curing, the panel offers outstanding resistance to scratches, stains, heat, and chemical exposure. Its robust surface maintains integrity and appearance even under intensive daily use.

Eco-Friendly and Healthy

Produced with low-emission materials and zero solvents, this panel meets international environmental standards. It is free from harmful VOCs, ensuring safe and sustainable interior spaces.

Product Details

Base Material: High-density MDF or particleboard

Surface Treatment: EB-cured anti-fingerprint coating

Thickness Range: 3mm–25mm

Standard Size: 1220mm × 2440mm (custom sizes available)

Finish Options: Super matte, soft-touch, and silky finishes

Color Range: Available in solid, neutral, metallic, and wood-grain tones

Applications: Kitchen cabinets, wardrobes, wall panels, office furniture, doors, and commercial interiors

Each panel undergoes a precise surface treatment and quality inspection process to ensure uniform texture, consistent color, and superior surface quality.

Product Advantages

Elegant Appearance

The ultra-matte surface minimizes glare and delivers a refined, premium aesthetic that enhances any interior design.

Anti-Fingerprint & Easy Maintenance

The innovative AFP layer prevents fingerprint marks, smudges, and oil stains, keeping the surface pristine with minimal cleaning.

High Durability

The EB-cured coating provides excellent hardness and resistance to wear, ensuring long-lasting beauty and performance.

Comfortable Touch

The smooth, velvety surface offers a pleasant tactile experience, making it ideal for high-end residential and commercial applications.

Environmentally Friendly

With no solvent emissions and minimal VOCs, the EB-Cured Anti-Fingerprint Panel supports eco-conscious architecture and healthy indoor living.