EB Decorative Board

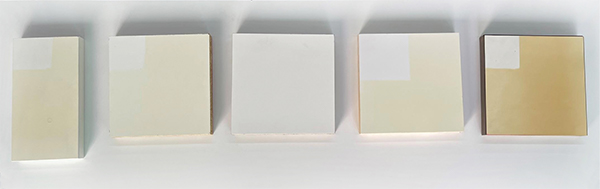

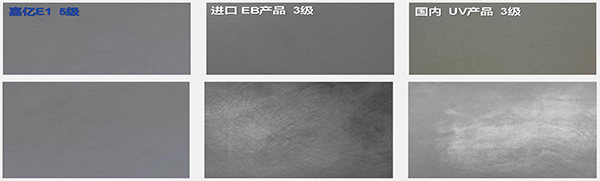

EBC electronic beam curing decorative panels, which are treated with a special surface curing technology EBC on the surface of ordinary phenolic resin decorative panels, endow them with super matte skin feel, anti-fingerprint, oil-proof, scratch-resistant and special scratch self-healing properties.

Product Description

EB curing = aerospace grade material + food grade process technology

EBC electronic beam curing decorative panels, which are treated with a special surface curing technology EBC on the surface of ordinary phenolic resin decorative panels, endow them with super matte skin feel, anti-fingerprint, oil-proof, scratch-resistant and special scratch self-healing properties. Compared with ordinary phenolic resin decorative board, because its surface uses a special process of electron beam curing, it brings a unique visual effect, its color is more full, true and pure. Color representation, product performance, environmental protection and health have achieved an unprecedented unity. Fusion of technology and design, creating infinite possibilities for custom brands and designers!

The EB Decorative Board is an advanced decorative material that combines aesthetic excellence with cutting-edge Electron Beam (EB) curing technology. Designed to meet the needs of modern interiors, this board delivers outstanding surface performance, durability, and environmental safety — making it the ideal choice for furniture manufacturing, wall panels, cabinetry, and commercial design applications.

Four characteristics

Technical

Test

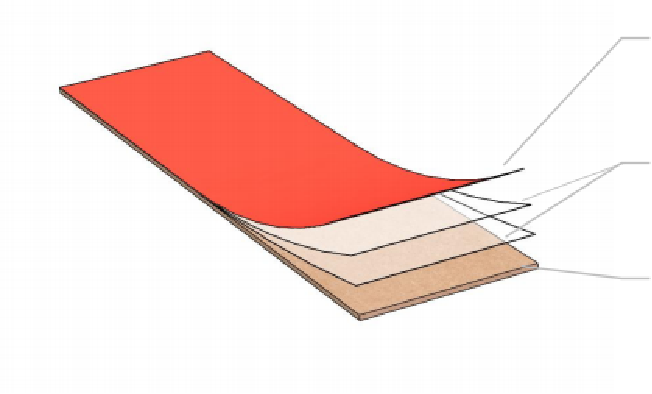

Production process

Face coating: color paint or varnish

Undercoat: colour paint or clear varnish

Base material: triazine or plain board

The production process of electron beam (EB) curing technology mainly uses high-energy electron beams to directly initiate polymerization or cross-linking reactions in materials, so that coatings, inks or resins can quickly solidify into films at room temperature. The process flow generally includes: raw material preparation, coating or sizing, electron beam irradiation curing and post-processing steps. During production, the electron beam curable resin system is first evenly coated on the surface of the substrate, and then under the protection of an inert atmosphere (usually nitrogen), an electron accelerator emits high-energy electron beams to irradiate the coating, causing the molecular chains to generate free radicals and rapidly cross-link and solidify. The entire process is completed in milliseconds. The EB curing production process has the advantages of fast curing speed, low energy consumption, no need for heating, no solvent emissions, uniform curing, and is suitable for heat-sensitive materials. It is widely used in packaging and printing, wood coating, electronic packaging, composite material manufacturing and other fields.

Product Features

Electron Beam (EB) Curing Technology

The EB Decorative Board utilizes a solvent-free curing process in which electron beams are used to form a dense, cross-linked surface layer. This innovative technology enhances hardness, chemical resistance, and color stability, giving the board superior durability compared to traditional UV or melamine panels.

High-Performance Surface

The EB-cured surface provides excellent resistance to scratches, stains, heat, and moisture. It maintains its original color and texture even under heavy daily use, ensuring long-lasting beauty and functionality.

Variety of Finishes and Textures

Available in multiple finishes — including matte, high-gloss, super matte, and soft-touch — the EB Decorative Board offers versatile design possibilities. It can replicate the look and feel of natural materials such as wood, marble, and metal with exceptional realism.

Eco-Friendly and Safe

The EB curing process is solvent-free and emits minimal volatile organic compounds (VOCs). It contributes to a healthier indoor environment and supports sustainable building practices.

Easy Maintenance

The board’s dense surface resists fingerprints, dirt, and water marks, making cleaning effortless. A simple wipe is enough to restore its clean, refined look.

Product Details

Base Material: High-quality MDF, particleboard, or plywood

Surface Treatment: EB-cured decorative coating

Thickness Range: 3mm–25mm

Standard Size: 1220mm × 2440mm (custom dimensions available)

Finish Options: Matte, high-gloss, soft-touch, anti-fingerprint, and textured

Applications: Furniture, kitchen cabinets, wardrobes, interior doors, wall cladding, and retail fixtures

Each panel undergoes precise surface treatment and quality inspection to ensure uniform gloss, color accuracy, and stable performance.

Product Advantages

Superior Durability

The EB-cured surface offers excellent resistance to scratches, impact, and fading, ensuring a long-lasting, flawless appearance.

Enhanced Aesthetic Appeal

With vibrant colors, realistic textures, and a wide range of finishes, the EB Decorative Board brings design flexibility and premium style to any space.

Easy to Clean and Maintain

The non-porous surface prevents stains and smudges, allowing effortless maintenance with just a soft cloth.

Environmental Responsibility

Produced without solvents or harmful emissions, this board aligns with green building standards and sustainable interior design principles.

Cost-Effective Performance

Combining beauty, strength, and longevity, the EB Decorative Board reduces replacement and maintenance costs, offering exceptional long-term value.