Phenolic High Pressure Decorative Laminates

Phenolic high pressure decorative laminates are made of phenolic resin as the base material, which is made into a grade of non-combustible board by foaming and curing. It has the characteristics of heat insulation, fire resistance, low smoke and environmental protection, and is used for building insulation and decoration.

Product Description

High pressure laminate

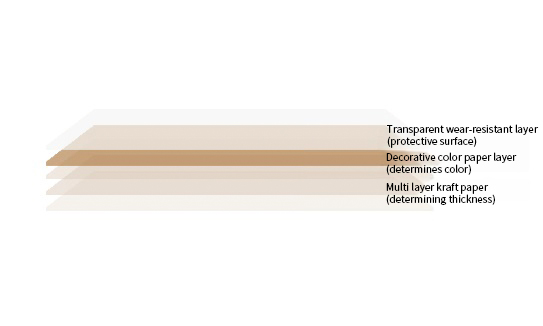

HPL (High Pressure Laminate) is a high-performance decorative material made by a high-temperature and high-pressure process.Made from high-grade decorative paper, kraft paper, and processed by impregnation, drying, high temperature and high pressure. Its core structure is by multiple layers of resin-impregnated paper, which is compressed and cured, it has many physical properties and decorative effects, and is widely used in construction, furniture, and other fields. HPL, with its comprehensive advantages of fire resistance, durability, and aesthetics, has become an important choice for modern decorative materials.

As a high-performance fireproof board innovator, we make every inch of space a carrier of aesthetics. Changzhou Giovanni provides the cornerstone for designers to create without boundaries. With a diverse range of colors, textures, and performance, it has become the ideal choice for enterprises to create visually appealing, comfortable, and forward looking spaces.

Phenolic high pressure decorative laminates are made of phenolic resin as the base material, which is made into a grade of non-combustible board by foaming and curing. It has the characteristics of heat insulation, fire resistance, low smoke and environmental protection, and is used for building insulation and decoration. Phenolic high pressure laminates have A-level fire resistance, good thermal insulation, low smoke and non-toxic, and can withstand high temperatures without.

Product Parameter (Specification)

| Sizes Available | 4*8 | 4.3*10 | 4*12 | 5*10 | 5*12 |

| Thickness Available | 0.5mm | 0.6mm | 0.7mm | 0.8mm | 1mm |

Product Details

Phenolic HPL consists of a core made from multiple sheets of kraft paper saturated with phenolic resin, giving the laminate its structural integrity and moisture resistance. The top layer features a decorative paper impregnated with melamine resin, which provides color, pattern, and protection. Available in a variety of thicknesses—from 0.7mm for standard interior surfaces to 12mm or more for self-supporting panels—these laminates can be used for horizontal, vertical, and even exterior-grade applications. Surface finishes include matte, gloss, textured, and anti-fingerprint options, offering both visual sophistication and functional performance.

Phenolic laminates come in a broad selection of designs such as solid colors, woodgrains, stones, metallics, and abstract patterns, allowing designers to create stylish and functional environments. The sheets are manufactured in standard sizes and can be customized according to project requirements.

Product Features

Exceptional Durability: The phenolic resin core provides high impact, scratch, and wear resistance, making it suitable for heavy-duty use.

Moisture and Heat Resistance: Non-porous and stable under high humidity or temperature changes, ensuring long-lasting performance in demanding environments.

Chemical and Stain Resistance: Resistant to most household and industrial chemicals, ideal for laboratories, hospitals, and commercial kitchens.

Aesthetic Versatility: Available in an extensive range of patterns, textures, and finishes to match diverse interior and architectural styles.

Hygienic and Easy to Maintain: The smooth, sealed surface prevents the growth of bacteria and is easy to clean with minimal maintenance.

Fire and UV Resistance: Meets international safety standards, offering enhanced resistance to fire and ultraviolet light degradation.

Eco-Friendly Manufacturing: Produced with low-emission resins and sustainable materials, compliant with environmental certifications.

Product Advantages

Phenolic High Pressure Decorative Laminates offer numerous advantages over conventional surfacing materials. Unlike standard laminates, the phenolic core adds rigidity, structural stability, and water resistance, allowing the laminate to be used in both dry and wet areas. They are self-supporting at higher thicknesses, eliminating the need for additional substrates. Compared with natural materials like wood or stone, phenolic laminates are lighter, more consistent, and significantly easier to fabricate and install.

Their exceptional resistance to impact, chemicals, and moisture makes them an ideal choice for high-traffic or high-performance areas such as laboratories, restrooms, hospitals, educational institutions, and transportation interiors. In addition, they maintain color stability and surface integrity even after prolonged exposure to sunlight and humidity.

Deliver and Payment method

Usually we ship goods by sea, because we are in Changzhou, we are very close to Shanghai port, and it is very convenient for export by sea. Of course, if the customer's goods are urgent, we can also air freight, Ningbo Airport and Shanghai International Airport are very close to us.

Payment method: When quoting, we will confirm with you the transaction method, FOB, CIF, CNF or other method. During mass production, we usually pay a 30% advance payment first, and then pay the balance on the bill of lading. Most of our payment methods are T/T, of course, L/C is also acceptable.

FAQ

(1)Colorful and versatile style

(2)Can be used for wall, furniture veneer and other decorative scenarios.

(3)Durable and easy to clean, easy maintenance

(4)Storage environment: Please place the boards in a ventilated and cool place, and do not store the boards in damp or exposed places.