Postforming High Pressure Laminate

Postforming high pressure laminate is a special high-pressure decorative board with excellent fire resistance. It is difficult to burn and can resist fire and smoke. After process treatment, it can be bent and formed at room temperature, and can adapt to arc and irregular structures. The surface is wear-resistant and heat-resistant, with rich texture and has the characteristics of safety, beauty and convenient construction.

Product Description

High Pressure Laminate

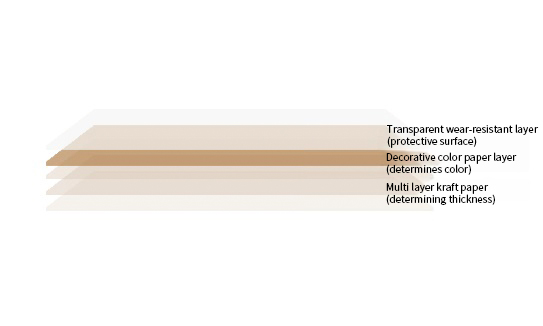

HPL (High Pressure Laminate) is a high-performance decorative material made by a high-temperature and high-pressure process.Made from high-grade decorative paper, kraft paper, and processed by impregnation, drying, high temperature and high pressure. Its core structure is by multiple layers of resin-impregnated paper, which is compressed and cured, it has many physical properties and decorative effects, and is widely used in construction, furniture, and other fields. HPL, with its comprehensive advantages of fire resistance, durability, and aesthetics, has become an important choice for modern decorative materials.

As a high-performance fireproof board innovator, we make every inch of space a carrier of aesthetics. Changzhou Giovanni provides the cornerstone for designers to create without boundaries. With a diverse range of colors, textures, and performance, it has become the ideal choice for enterprises to create visually appealing, comfortable, and forward looking spaces.

Postforming high pressure laminate is a special high-pressure decorative board with excellent fire resistance. It is difficult to burn and can resist fire and smoke. After process treatment, it can be bent and formed at room temperature, and can adapt to arc and irregular structures. The surface is wear-resistant and heat-resistant, with rich texture and has the characteristics of safety, beauty and convenient construction.

Product Parameter (Specification)

| Sizes Available | 4*8 | 4.3*10 | 4*12 | 5*10 | 5*12 |

| Thickness Available | 0.5mm | 0.6mm | 0.7mm | 0.8mm | 1mm |

Product Details

Postforming HPL sheets are designed for flexibility and durability. The standard thickness ranges from 0.6mm to 1.0mm, optimized for bending under controlled heat conditions to achieve rounded or contoured profiles. The decorative surface is available in a wide variety of designs, including solid colors, woodgrains, metallics, stone effects, and abstract patterns. Finishes such as gloss, matte, textured, and silk-touch enhance visual appeal and tactile quality. The core layers are reinforced with phenolic resin for stability, while the top layer features melamine resin for superior resistance to scratches, heat, and stains.

Product Features

Excellent Postforming Capability: Specifically designed to be heated and formed into smooth curves, allowing for elegant, seamless edges and continuous surface transitions.

Superior Surface Performance: Resistant to wear, impact, heat, moisture, and household chemicals, ensuring long-term durability in both horizontal and vertical applications.

Aesthetic Versatility: Offers a broad range of colors, textures, and patterns to match any interior design style—from minimalist modern to classic elegance.

Easy Cleaning and Maintenance: The non-porous melamine surface resists dirt and bacteria, making it hygienic and easy to maintain.

Lightweight and Flexible: Easier to handle and install compared to traditional surfacing materials like natural stone or solid surfaces.

Eco-Friendly Production: Manufactured using sustainable materials and low-emission resins, compliant with international environmental standards.

Product Advantages

Postforming High Pressure Laminates provide distinct advantages over conventional laminates and other surfacing materials. Their ability to form smooth curves eliminates the need for visible joints and edge trims, creating a seamless and elegant appearance. This feature not only enhances aesthetic value but also improves hygiene by minimizing dirt accumulation along edges. The laminates’ superior resistance to impact, abrasion, and heat ensures reliable performance even in demanding environments such as kitchens, laboratories, hospitals, and commercial interiors.

Compared with solid surfaces and natural materials, Postforming HPL is cost-effective, lightweight, and more adaptable for creative applications. Its flexibility allows for unique design possibilities such as waterfall edges, rounded countertops, and curved furniture panels. Additionally, it provides consistent color, texture, and finish across large-scale projects, something difficult to achieve with natural materials.

Deliver and Payment method

Usually we ship goods by sea, because we are in Changzhou, we are very close to Shanghai port, and it is very convenient for export by sea. Of course, if the customer's goods are urgent, we can also air freight, Ningbo Airport and Shanghai International Airport are very close to us.

Payment method: When quoting, we will confirm with you the transaction method, FOB, CIF, CNF or other method. During mass production, we usually pay a 30% advance payment first, and then pay the balance on the bill of lading. Most of our payment methods are T/T, of course, L/C is also acceptable.

FAQ

(1)Flexible and malleable, can be attached to curved structures.

(2)Rich texture; easy to install.

(3)Storage environment: Please place the boards in a ventilated and cool place, and do not store the boards in damp or exposed places.