Phenolic High Pressure Laminates

HPL (High Pressure Laminate) is a high-performance decorative material made by a high-temperature and high-pressure process.Made from high-grade decorative paper, kraft paper, and processed by impregnation, drying, high temperature and high pressure.

Product Description

HPL (High Pressure Laminate) is a high-performance decorative material made by a high-temperature and high-pressure process.Made from high-grade decorative paper, kraft paper, and processed by impregnation, drying, high temperature and high pressure. Its core structure is by multiple layers of resin-impregnated paper, which is compressed and cured, it has many physical properties and decorative effects, and is widely used in construction, furniture, and other fields. HPL, with its comprehensive advantages of fire resistance, durability, and aesthetics, has become an important choice for modern decorative materials.

As a high-performance fireproof board innovator, we make every inch of space a carrier of aesthetics. Changzhou Giovanni provides the cornerstone for designers to create without boundaries. With a diverse range of colors, textures, and performance, it has become the ideal choice for enterprises to create visually appealing, comfortable, and forward looking spaces.

Phenolic High Pressure Laminates (HPL) are premium-grade surfacing materials engineered for maximum durability, strength, and versatility. Produced by compressing multiple layers of kraft paper impregnated with phenolic resin under high temperature and pressure, these laminates deliver a dense, non-porous, and highly resilient surface. With excellent resistance to impact, moisture, heat, and chemicals, Phenolic HPL is widely used in demanding applications such as furniture, wall panels, doors, countertops, partitions, laboratory benches, public restrooms, and exterior cladding, offering both functional performance and aesthetic appeal.

Product Details

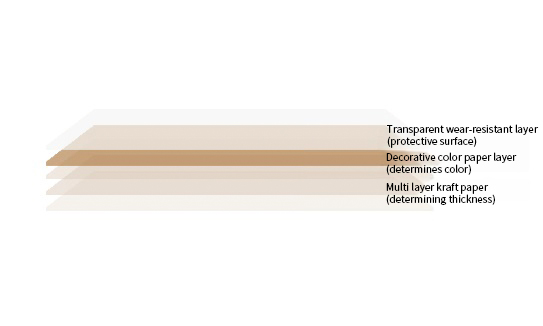

Phenolic HPL sheets consist of a core made from layers of kraft paper saturated with phenolic resin, providing structural stability, rigidity, and water resistance. The surface layer is composed of decorative paper impregnated with melamine resin, offering color, pattern, and protection. Standard thicknesses range from 0.7mm for general interior surfaces to 12mm or more for self-supporting panels. The laminates are available in a variety of finishes, including matte, gloss, textured, and anti-fingerprint, catering to both design and practical requirements.

A wide selection of designs is offered, from solid colors and woodgrains to stone, metallic, and abstract patterns, enabling architects and designers to create sophisticated and contemporary interior spaces. Sheet sizes can be customized to meet specific project demands, ensuring seamless integration into diverse applications.

Product Features

High Strength and Durability: The phenolic core provides exceptional resistance to impact, scratches, and wear, making it ideal for high-traffic areas.

Moisture and Heat Resistance: Non-porous and stable under varying humidity and temperature, suitable for both interior and exterior applications.

Chemical and Stain Resistance: Withstands most household and industrial chemicals, ideal for laboratories, kitchens, and healthcare facilities.

Wide Design Range: Available in numerous colors, patterns, and finishes, allowing versatile applications in modern and traditional designs.

Hygienic and Easy to Maintain: Smooth, sealed surface prevents bacterial growth and simplifies cleaning and maintenance.

Fire and UV Resistance: Meets international safety standards, providing enhanced protection against fire and ultraviolet degradation.

Eco-Friendly Manufacturing: Produced with low-emission resins and sustainable materials in compliance with environmental regulations.

Product Advantages

Phenolic HPL offers significant advantages over conventional laminates and natural materials. Its high structural integrity allows for self-supporting panels in thicker grades, reducing the need for additional substrates. Compared to wood or stone, phenolic laminates are lightweight, uniform in appearance, and easier to fabricate, cut, and install.

In addition, their outstanding resistance to moisture, heat, chemicals, and UV light makes them suitable for a wide range of challenging environments, from public and commercial spaces to laboratories and healthcare facilities. The laminates maintain consistent color, texture, and surface integrity over time, ensuring long-lasting performance.