High Pressure Laminates

HPL (High Pressure Laminate) is a high-performance decorative material made by a high-temperature and high-pressure process. Made from high-grade decorative paper, kraft paper, and processed by impregnation, drying, high temperature and high pressure. With a diverse range of colors, textures, and performance, it has become the ideal choice for enterprises to create visually appealing, comfortable, and forward looking spaces.

Product Description

High pressure laminate

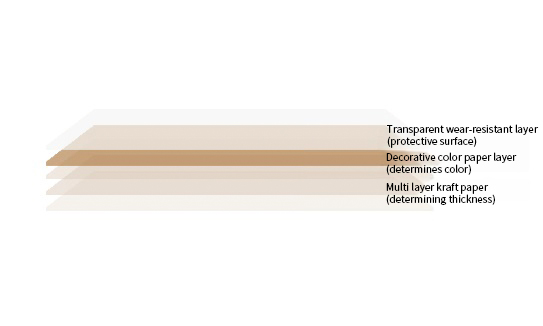

The structure of HPL

1.Surface: composed of decorative color paper impregnated with melamine resin, providing a rich variety of colors, textures (such as wood grain, stone grain), and surface effects (matte, high gloss, embossed).

2.Core layer: multi-layer impregnated phenolic resin paper, which is pressed at high temperature and high pressure to form a high-strength substrate, the board the characteristics of impact resistance and wear resistance.

3.Bottom layer: Decorative paper layer, used to stabilize the size of the board and prevent deformation.

4.Surface transparent layer: can effectively protect the base material, enhance surface performance, effectively resist external wear, stains and chemical corrosion, and keep the board clean a long time.

HPL (High Pressure Laminate) is a high-performance decorative material made by a high-temperature and high-pressure process.Made from high-grade decorative paper, kraft paper, and processed by impregnation, drying, high temperature and high pressure. Its core structure is by multiple layers of resin-impregnated paper, which is compressed and cured, it has many physical properties and decorative effects, and is widely used in construction, furniture, and other fields. HPL, with its comprehensive advantages of fire resistance, durability, and aesthetics, has become an important choice for modern decorative materials.

As a high-performance fireproof board innovator, we make every inch of space a carrier of aesthetics. Changzhou Giovanni provides the cornerstone for designers to create without boundaries. With a diverse range of colors, textures, and performance, it has become the ideal choice for enterprises to create visually appealing, comfortable, and forward looking spaces.

High Pressure Laminates (HPL) are premium surfacing materials known for their outstanding durability, versatility, and elegant appearance. Manufactured through a high-pressure and high-temperature process, HPL is created by compressing multiple layers of kraft paper impregnated with phenolic resin and a decorative paper layer coated with melamine resin. The result is a dense, non-porous, and highly resilient material that offers both aesthetic appeal and superior performance. High Pressure Laminates are widely used in furniture, interior decoration, wall cladding, countertops, doors, cabinets, and commercial spaces, making them one of the most popular and reliable decorative surface materials available today.

Core advantages

1.Wear and scratch resistance: The surface has been specially treated with excellent wear resistance. It is difficult to leave obvious traces on the surface during daily use, it can maintain beauty for a long time.

2.Chemical resistance: It can be applied to chemical laboratories, hospitals and other places, and has strong resistance to acid and alkali chemical substances.

3.Fireproof performance: It has good flame retardant performance, will not burn when exposed to fire source, can effectively resist the spread of fire, will not produce toxic gas smoke, in line with national fire standards.

4.Vibrant colors, versatile style: Hundreds of patterns to choose from, including natural wood grain, stone texture, fabric pattern, metallic feel and solid color easily matching various design styles such as modern simplicity, natural luxury and industrial style.

5.Durable and easy to clean, easy maintenance: HPL surface is smooth and dense, matched with a transparent and stain-resistant protective layer, making it difficult for water stains and soap scum to penetrate. Cleaning only requires a damp cloth wipe, and stubborn stains can be easily removed with neutral cleaners or alcohol, effectively reducing the cost of cleaning and maintenance of the bathroom.

6.Environmental performance: excellent environmental performance, made of environmentally friendly resin and wood fiber by high temperature pressing, no formaldehyde release, more in line the national green building materials requirements, to provide consumers with a healthy and comfortable living environment.

Product Details

Each HPL sheet is composed of three main components: kraft paper layers for structural strength, phenolic resin for bonding and durability, and melamine resin on the surface for visual appeal and protection. The laminates are pressed under temperatures of over 140°C and pressures exceeding 1000 psi to produce a hard, uniform, and stable material.

HPL comes in a wide variety of thicknesses—typically from 0.6mm to 1.2mm for standard applications, and up to 12mm for compact grades used in self-supporting panels. The surface layer is available in various finishes such as matte, glossy, textured, embossed, and soft-touch, each offering a unique aesthetic and tactile experience. The decorative designs include solid colors, woodgrains, marble, stone, metallic, and abstract patterns, providing endless design possibilities for architects and interior designers.

Product Features

Exceptional Durability: Highly resistant to scratches, impact, abrasion, and general wear, ensuring long-lasting performance in demanding environments.

Moisture and Heat Resistance: The non-porous structure provides excellent resistance to water and high temperatures, making it suitable for kitchens, bathrooms, and laboratories.

Easy to Clean and Maintain: The sealed surface repels dirt, stains, and bacteria, allowing for quick and effortless cleaning.

Extensive Design Options: Available in a vast array of colors, patterns, and textures to suit modern, classic, or industrial design themes.

Fire and UV Resistance: Complies with international safety standards, ensuring resistance to fire and ultraviolet degradation.

Dimensional Stability: Maintains flatness and shape even under fluctuating temperature and humidity conditions.

Eco-Friendly Production: Manufactured using sustainable raw materials and low-emission resins that meet environmental protection standards.

Product Advantages

High Pressure Laminates offer multiple advantages over traditional materials such as solid wood, paint finishes, and natural stone. They combine the beauty of natural textures with superior mechanical performance, providing a surface that is both elegant and durable. Unlike wood, HPL does not warp, fade, or require refinishing. Compared with stone, it is lighter, easier to install, and more cost-effective.

HPL’s adaptability makes it suitable for both horizontal and vertical surfaces, and it can be applied to various substrates like MDF, particleboard, or plywood. In thicker grades, it can even be used as a self-supporting material for partitions or wall panels. Its hygienic and easy-to-clean surface makes it ideal for use in healthcare, hospitality, education, and commercial environments.

Application scenarios

1.Architectural decoration:

The overall decoration of public spaces such as walls, partitions, hotels, shopping malls, and schools.

Facade cladding: UV-resistant HPL for exterior building facades, combining decoration and protection.

2.Furniture manufacturing;:

Cabinet, wardrobe, desktop: Its moisture-resistant and easy-to-clean properties make it a preferred choice for kitchen and bathroom furniture

Office furniture: wear-resistant and impact-resistant performance suitable for high-frequency office environment.

3.Traffic and industry:

Interior of the car: lightweight design meets the automotive industry's environmental and safety needs.

Vessels, high-speed trains: fire and moisture resistance meet the strict standards of transportation.

4.Other filed:

Laboratory bench top: chemical corrosion resistance performance to protect experimental equipment and personnel safety.

Anti-static flooring: HPL flooring used in machine rooms and data centers can effectively release static electricity.

Different thickness differences:

Standard HPL: thickness 0.35-2mm, mainly used for wall, furniture veneer and other decorative scenarios.

Compact Laminate: Thickness 2-30mm, with higher density and greater strength, suitable for washroom partitions, outdoor wall panels and other scenarios with strict durability requirements.

Industry standards and certifications

1.Fire protection standard:

Domestic: GB8624-2012 "Building Material Fire Performance Grading" (B1/A2 grade)

International: ISO 4586 series standards (Specifications for high pressure decorative laminates).